In August 2021, Western Heritage Furniture (WHF) customers Wendy & Raul Meoz ordered a customized bedroom set for a newly-designed bedroom in their Sedona home.

Wendy approached WHF fully prepared with a vision of the design she felt would not only suit the space but also meet their functionality needs. With dimensions in hand, we worked closely with the Meozes to build them the bedroom set of their dreams.

THE DESIGN PROCESS

The design process is the first phase in building a custom bedroom set. The initial step is ensuring all the dimensions for the pieces are correct.

For example, when building beds, mattress thickness and box spring height are important factors. Not only do we need to make the overall mattress height meet a client’s requirements, but these dimensions also impact how high the side rails will clear off the floor. And in the case of this project, the bedroom’s ceiling was a bit low, limiting the height we could make the bed.

Once Wendy and the WHF team finalized the dimensions, we began the overall design look. This includes a lot of back-and-forth discussion of wood samples and images of other furniture pieces for design ideas.

For the bed’s headboard, the Meozes decided on an arched headboard design. As the bed’s placement is under four window panes, we felt this would better feature the headboard.

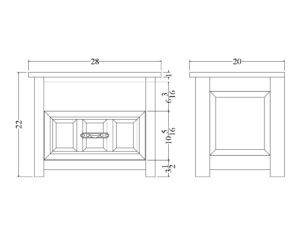

A photo Wendy sent us helped in the design of the bedroom set’s nightstands. The tops of the nightstands feature the same granite countertops used in the bedroom’s connecting bathroom. Main Place in Cottonwood, AZ, handled cutting the nightstand granite tops to the size we needed and the bullnose edge work.

MOVING INTO PRODUCTION

After extensively discussing color tones and barn wood placement, and receiving final approval on drawings, we began production on the custom bedroom set.

At this stage, our engineer, lead project craftsman, and myself meet for an in-depth design and build session. We go over every function and design detail in exacting language, which is all documented at the meeting in our operating system. Supporting finish samples, pictures, drawings, and all other project documents are all clearly labeled for reference.

The building begins with culling and picking the reclaimed wood for the overall approved look. I pick and approve all the detail wood pieces.

As the building progresses and some semblance of a piece of furniture evolves, I send progress pictures to the client. As some pictures may be hard to understand, I provide explanations as to what they are looking at within the design process.

Because Wendy had her contractor’s hat on due to her remodel, she got to see more of the beginning of build pictures. When we completed the bedroom set, we set up how it would look in our shop and sent her pictures for her final approval.

The WHF team hand-delivered and installed the Meoz bedroom set on October 29, 2021. They were very happy with the results!

UNIQUE DESIGN DETAILS

We use many building techniques and hardware that are not common in the furniture readily available today. These special details not only elevate the quality of the furniture but also the overall look and feel of each piece.

Here’s a closer look at some of the unique design details used in the Meoz bedroom set.

LAMINATED CURVED BARN WOOD VENEER ON THE HEADBOARD RADIUS

We have been using this technique for the past seven years, and to date, I have not seen another barn wood furniture builder use it. This allows us to utilize bended curves on round tables and arches, while still showcasing the aged weathered wood on all surfaces. See the detailed shots of the headboard for reference.

BOXED HEADBOARD UPRIGHTS AND FOOT BOARD FEET

We build a solid wood core and then apply the approved wood skins to the core. This allows the grain directions to align, making the piece more structurally sound.

DRAWER BOXES & HARDWARE

We made each drawer box from solid wood with hand-cut, half-blind dovetail joints. And the drawer hardware is soft-touch and self-closing, so the drawers open and close as smooth as butter!

WAXING

After applying a lacquer finish to all pieces, everything is hand waxed with the best wax on the market. We literally apply the wax with a nylon brush in no more than three-inch square areas and then vigorously rub it with cotton rags. It’s an intense shoulder workout! We’ve tried machines to do this but the result is not up to our standards.

HEIRLOOM-QUALITY BEDROOM SETS IN JEROME, ARIZONA

Wendy & Raul Meoz were an absolute delight to work with. We love being able to bring a particular furniture design vision to life. WHF is grateful for every client we have and are honored that they have chosen our furniture to include in their home. We do not take this responsibility lightly at WHF. Assuring the joy of clients with their furniture pieces is our obligation.

If you would like to discuss making your dream furniture a reality, call Western Heritage Furniture today at 928-852-0061.